Product

Technologic High-Flyer

Logistics

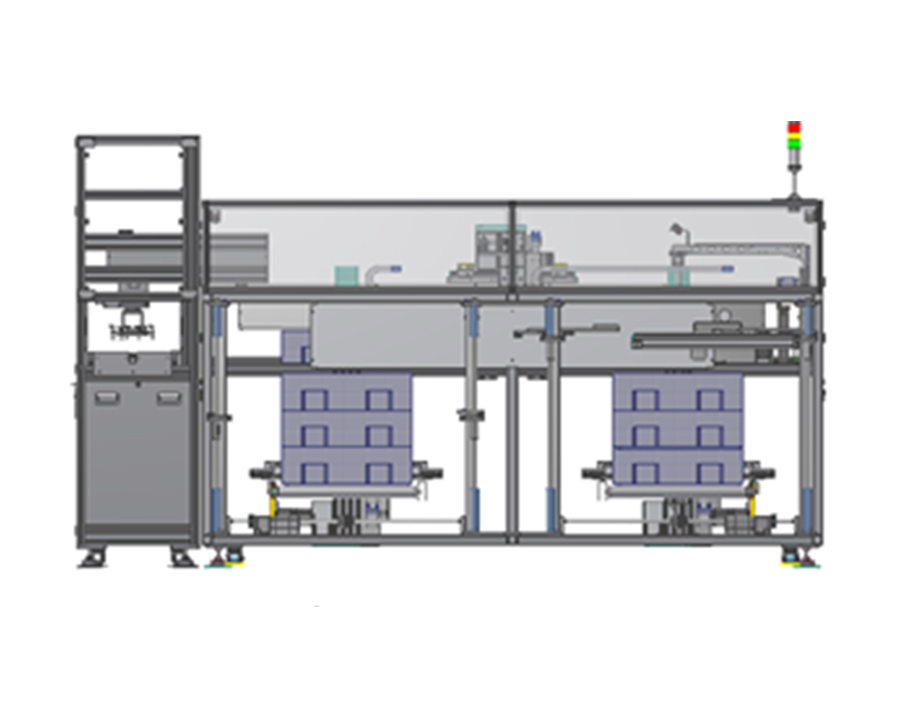

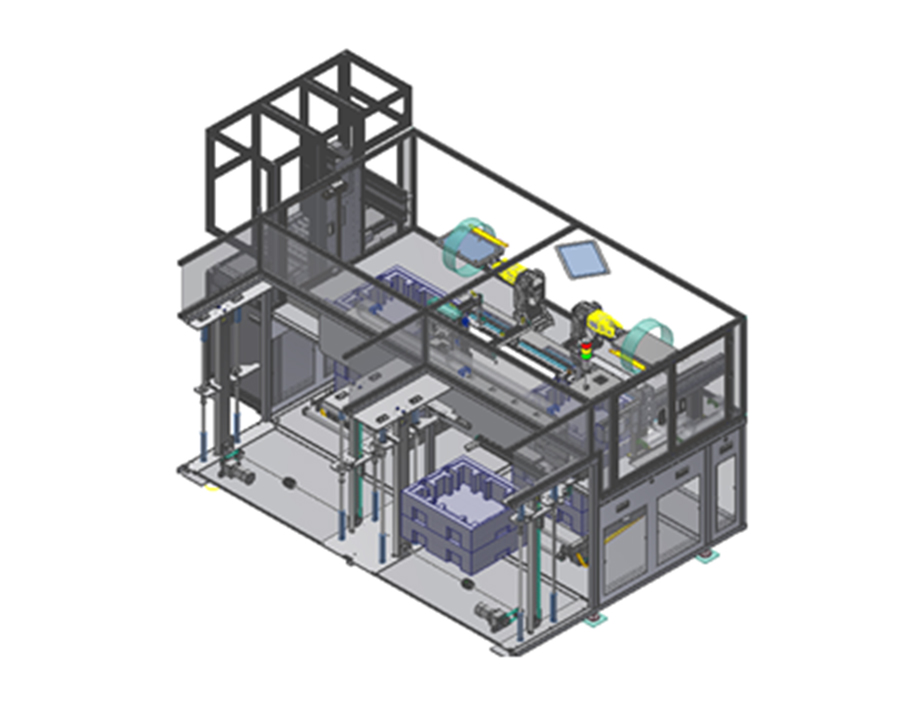

AR TESTER LOADER

Equipment retransferring panels to the next/previous facilities using the loading/unloading handler and 6-axis stage handler.

Carrying in and out of panels are performed via an Epp box. The Epp boxes are automatically moved in and out by a conveyor using Agv or hand push type car. Also, the box lift and box transfer are used. In case of panel unloading, the NG products are carried out via a NG conveyor.

Specification

| TACT TIME | 13 sec | ||

|---|---|---|---|

| Corresponding PANEL | 7.9"/ 9.7" / 12.9" | ||

| Box moving logistics | Corresponding AGV | One side | |

| EPP BOX (Appearance tolerance1.3~2.5mm) | 7.9" | 571 X 487 X 112 | Necessary to check the quantity of loaded slip sheets |

| 9.7" | 630 X 560 X 179.5 | Necessary to check the quantity of loaded slip sheets | |

| 9.7" | 571 X 487 X 112 | Necessary to check the quantity of loaded slip sheets | |

| Material (box) replacement time | |||

| AGV supply stages | 7.9"/12.9" | 5 stages | maximum height |

| 9.7" | 3 stages | ||

| Slip sheet moving method | HANDLER / Vacuum suction | Movement : Motor, Vacuum Up/Down : CYLINDER | |

| Moving method of work zone box | HANDLER / Gripper | Movement : Motor, Vacuum Up/Down : CYLINDER | |

| AGV Pass Line | 400mm | In/Out detection sensor | |

| Back-end process pass line | 1250 ~ 1300mm | ||

| Logistics in equipment | Loading in the lower part / Unloading from the upper part. | Please refer to the separate layout | |

| Control method | PC & PLC | Vision PC and robot controller corresponding to the Samsung’s standards. | |

| Environmental safety | CE Mark & KCS certification | Observation of Samsung's Environmental Safety Standards | |